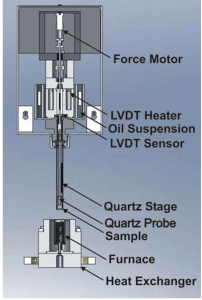

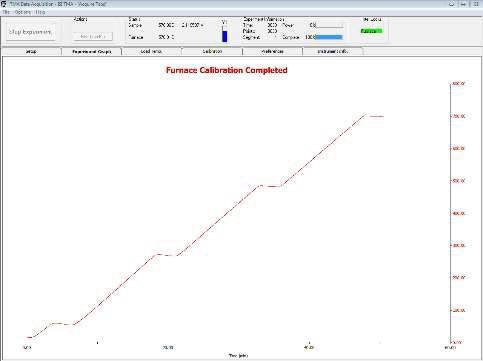

- The TMA 800 is built on a proven vertical design that incorporates an advanced Oil Float Suspension System, delivering the stability and precision required for accurate measurement of thermal expansion, glass transition, and other thermomechanical properties across a wide range of materials.

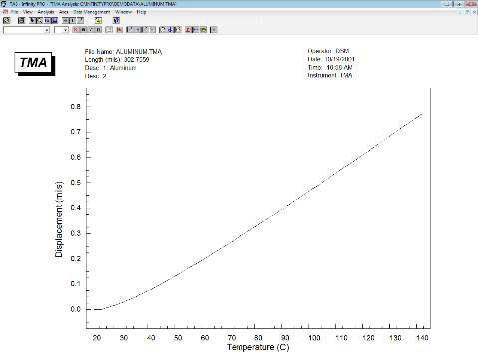

- Engineered for both performance and ease of use, the TMA 800 provides exceptional data quality for analyzing coefficients of thermal expansion (CTE), stress relaxation, and dimensional change. It is ideally suited for high-reliability applications in electronics, composites, advanced polymers, and more. With a wide operating temperature range from -90 °C to 800 °C and multiple test modes available, the TTMA 800 offers outstanding versatility to meet a broad range of application needs.

- Thermal expansion is a primary cause of mechanical stress and failure in electronic components, PCB assemblies, and multilayer structures. Accurately determining the glass transition temperature—the point at which softening and stress relief begin—or the onset of delamination is critical to product development, performance, and reliability in thermal environments.

Advanced Measurement Instruments

Copyright 2004–2024 ami-instruments.com

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com