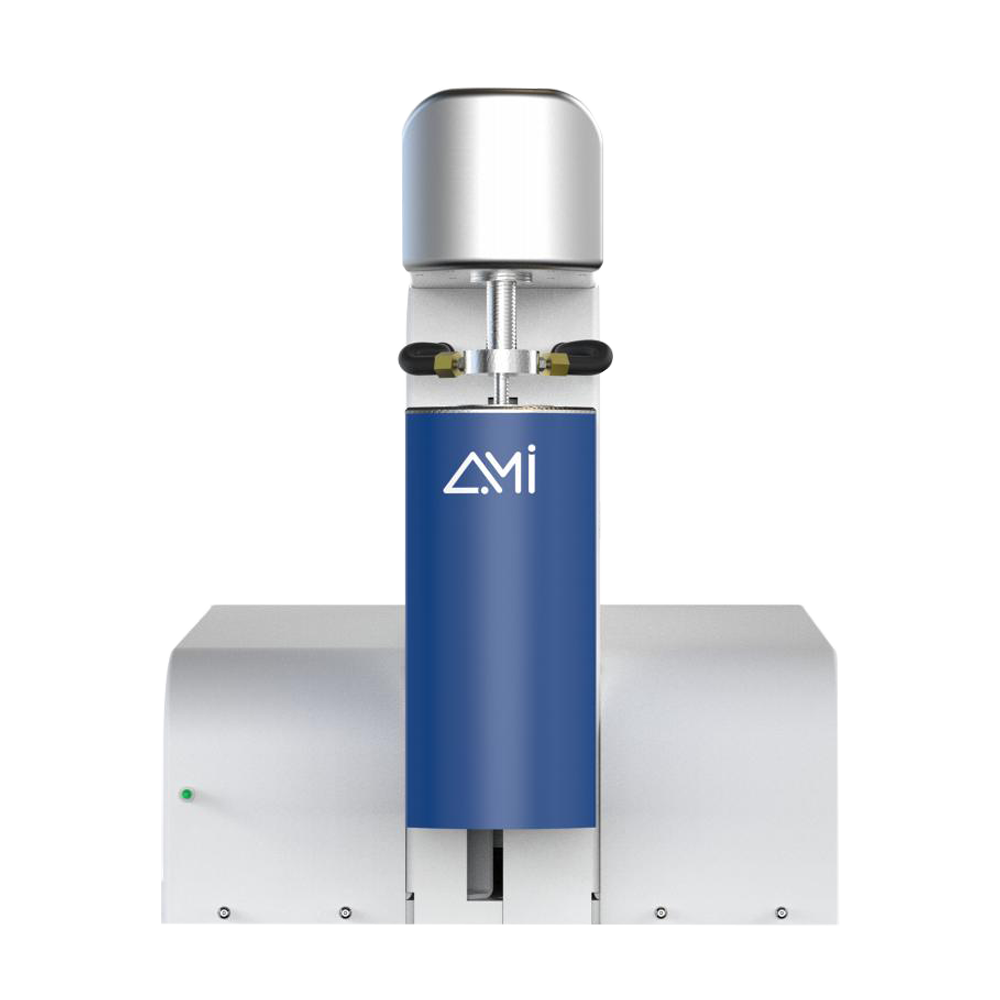

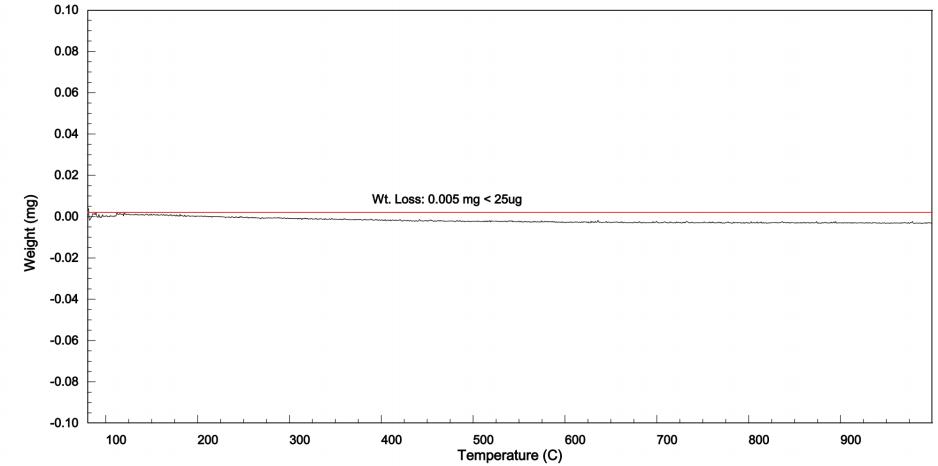

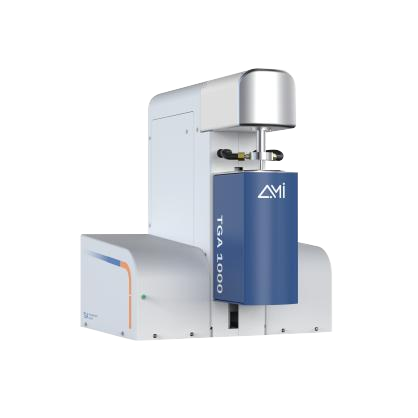

- Based in Wisconsin, Advanced Measurement Instruments (AMI) has been shaping the future of thermal analysis since 1992. With a steadfast commitment to innovation and precision, the company has become a trusted partner for professionals seeking advanced yet affordable solutions. At the forefront of the offerings is the Thermogravimetric Analyzer (TGA) Series, a product line that exemplifies cutting-edge design, exceptional performance, and unmatched value. The TGA Series combines research-grade capabilities with an accessible price point, delivering high-performance thermal analysis tools without compromising on quality. Equipped with advanced high-sensitivity microbalances and compact, state-of-the-art furnaces, these instruments provide unparalleled precision, drastically reduce buoyancy effects, and ensure superior temperature responsiveness.

- Renowned for their reliability and versatility, the TGA Series instruments are trusted across a wide range of industries, including plastics, rubber, adhesives, fibers, pharmaceuticals,environmental energy, petrochemicals, and food science. These instruments meet critical customer needs by enabling the characterization and analysis of parameters such as material decomposition temperatures, mass loss percentages, component contents, and residual mass.

Advanced Measurement Instruments

Copyright 2004–2024 ami-instruments.com

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com