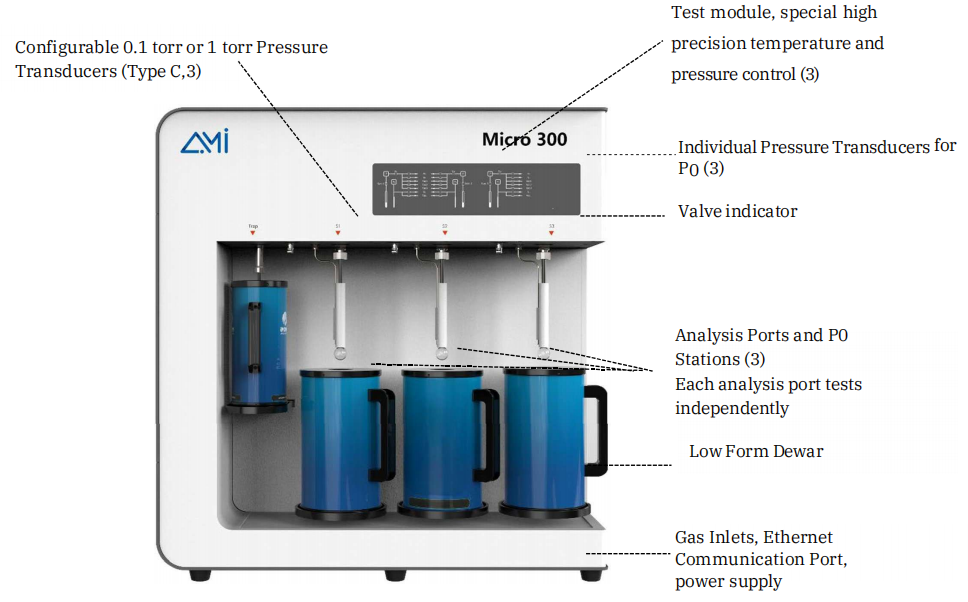

- The AMI-Micro 300 Series is a high-precision physisorption instrument designed for specific surface area and pore size analysis of various materials. It is equipped with three independently operating analysis ports, allowing different adsorbate gases to be configured and tested simultaneously. Based on functional capabilities, the series is categorized into three models: A, B, and C (see the specification table for additional details). Each analysis station features a dedicated dosing manifold to optimize analysis time and ensure precise gas dosing.

- The Micro 300 B and C models are equipped with a 1 torr or 0.1 torr high-sensitivity pressure transducers and a turbo molecular pump with an ultimate pressure of 10-8 Pa, ensuring precise measurements of microporous structures. Furthermore, all three analysis stations support in-situ sample preparation, minimizing the risk of contamination. This instrument is particularly well-suited for the characterization of microporous materials, including MOFs, molecular sieves, catalysts, activated carbon, and other porous substances.

Advanced Measurement Instruments

Copyright 2004–2024 ami-instruments.com

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com