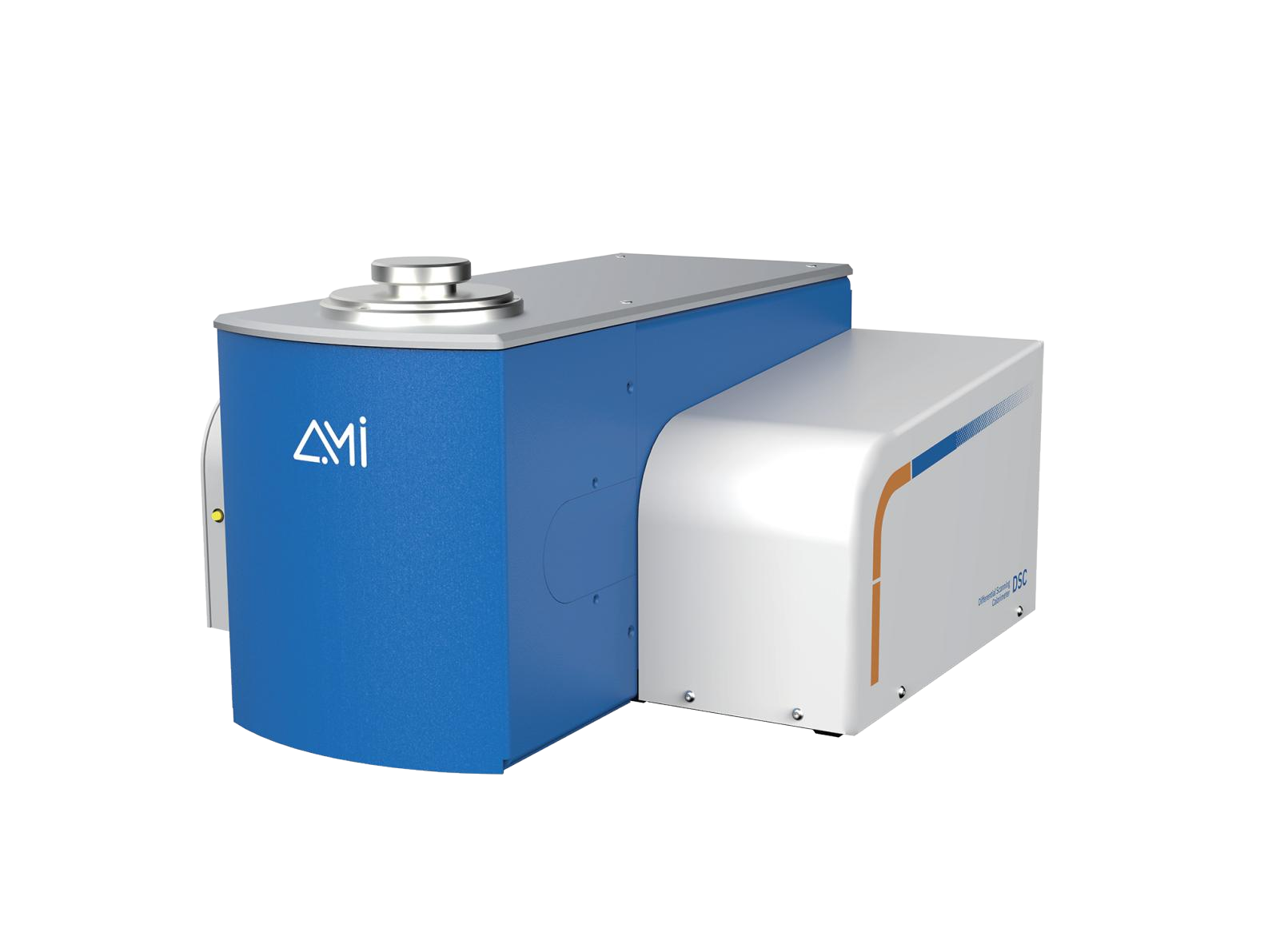

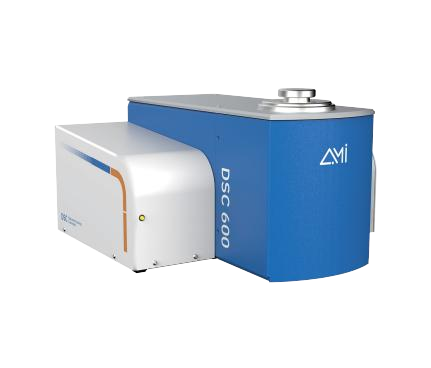

- The DSC 600 from Advanced Measurement Instruments (AMI) is the next generation of Differential Scanning Calorimeters (DSC), crafted to meet the evolving needs of professionals in materials research, chemical engineering, quality control, petrochemicals, and pharmaceuticals. Designed for precision, reliability, and affordability, the DSC 600 sets new standards in thermal analysis.

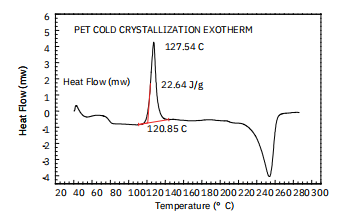

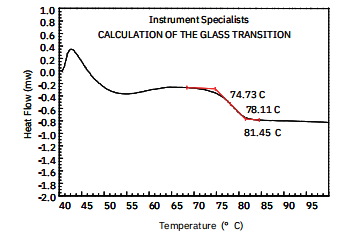

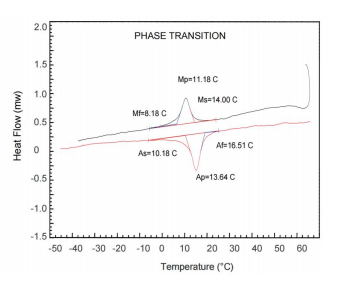

- At the heart of the DSC 600 is its innovative heat flux plate, engineered to capture the smallest energy changes with unmatched sensitivity and accuracy. This powerful capability enables precise measurements across a broad spectrum of applications, including enthalpy, glass transition, heat of crystallization, purity determination, and heat capacity.

- Equipped with an ultra-light furnace, the DSC 600 ensures excellent thermal conductivity and stability, delivering consistent performance across a wide temperature range. With a selection of specialized heat flux plates, it can be tailored to meet diverse testing needs,enhancing efficiency and flexibility in every lab.

Advanced Measurement Instruments

Copyright 2004–2024 ami-instruments.com

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com