- True density is a critical physical property for solid materials—especially powders—affecting everything from product performance to quality control. True density reflects a material’s purity and structural compactness, both of which play a direct role in its end-use properties.

- Traditionally, density has been measured using Archimedes' water displacement method. However, this approach suffers from manual error, liquid drainage issues, and poor repeatability. In response, the International Organization for Standardization (ISO) adopted the gas displacement method (ISO 12154) as the official standard for true density measurement in 2014.

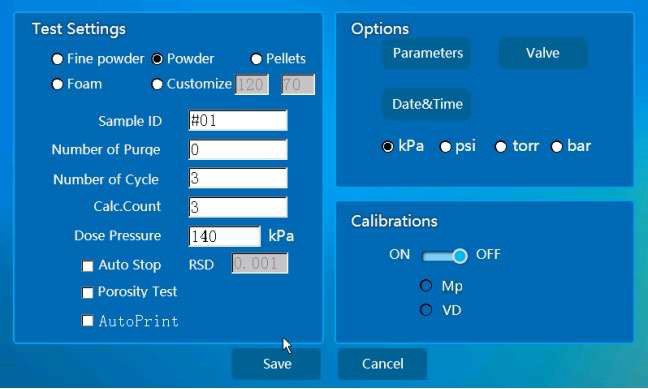

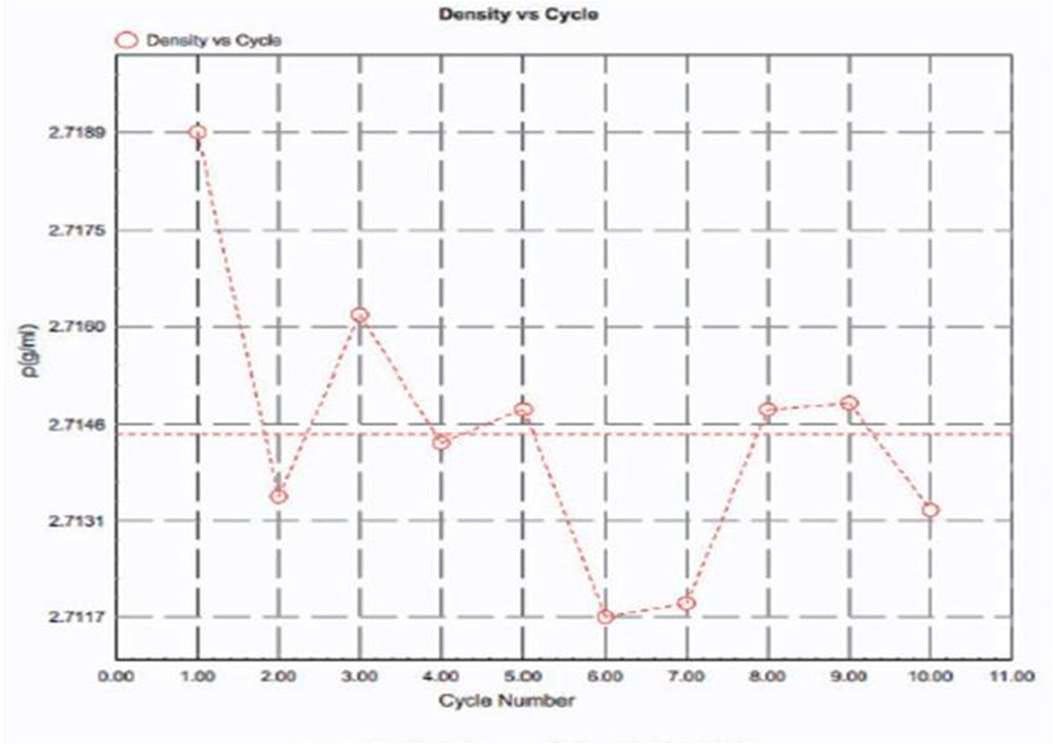

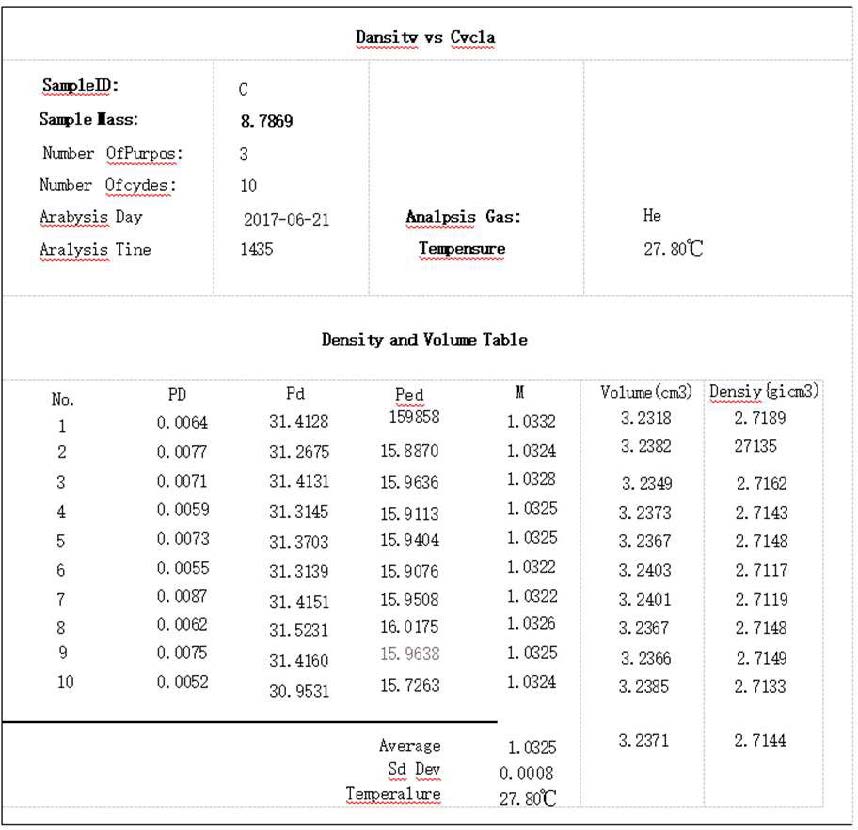

- The Densi 100 True Density Analyzer quickly and accurately determines the true volume and true density of a wide range of solid materials, including powders, granules, and solid blocks. With a sample chamber volume range of 1 cm³ to 100 cm³, the system accommodates both small and large samples. Each analysis is completed in approximately 3 minutes, delivering reliable results without compromising accuracy.

- √ TEST GAS: Helium or Nitrogen

√ Characteristic: Non-Destructive

√ Resolution: 0.0001 g/ml

√ Repeatability: +/- 1%

Advanced Measurement Instruments

Copyright 2004–2024 ami-instruments.com

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com