- AMI has extensive experience in the design and construction of BenchCAT reactors for biofuel applications. The study of biofuel processes has become a significant area of research in recent years. Although still largely in the research stage, substantial progress is being made, making the development of a commercial process likely in the near future.

- Biofuel is a broad term referring to any fuel not derived from fossil sources. In its simplest form, it can be ethanol produced from sugarcane or corn via fermentation. However, alcohol-based fuels lack the energy density of conventional fossil fuels like gasoline or diesel. Current efforts are focused on developing biofuels that closely resemble gasoline or diesel in their properties and performance.

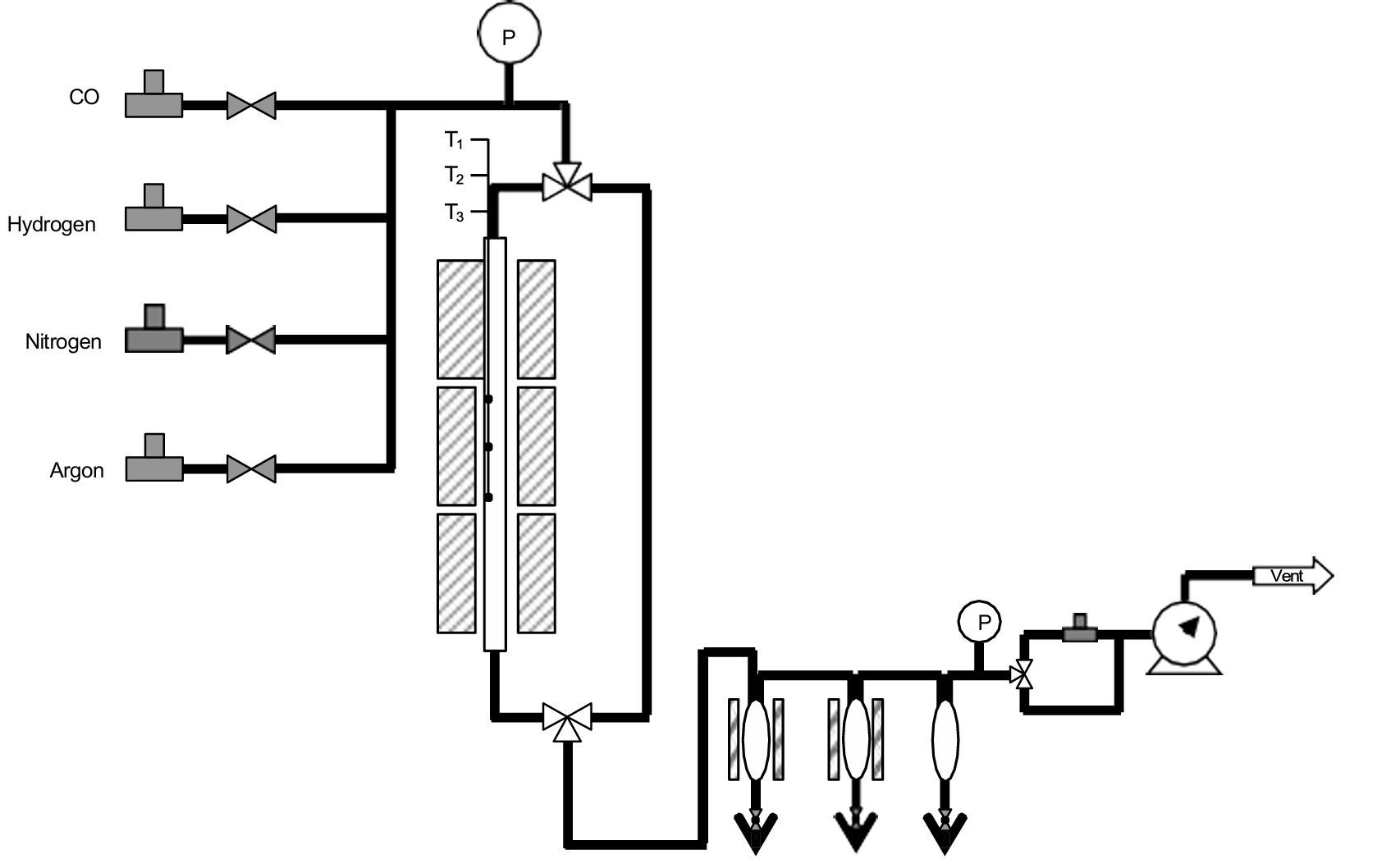

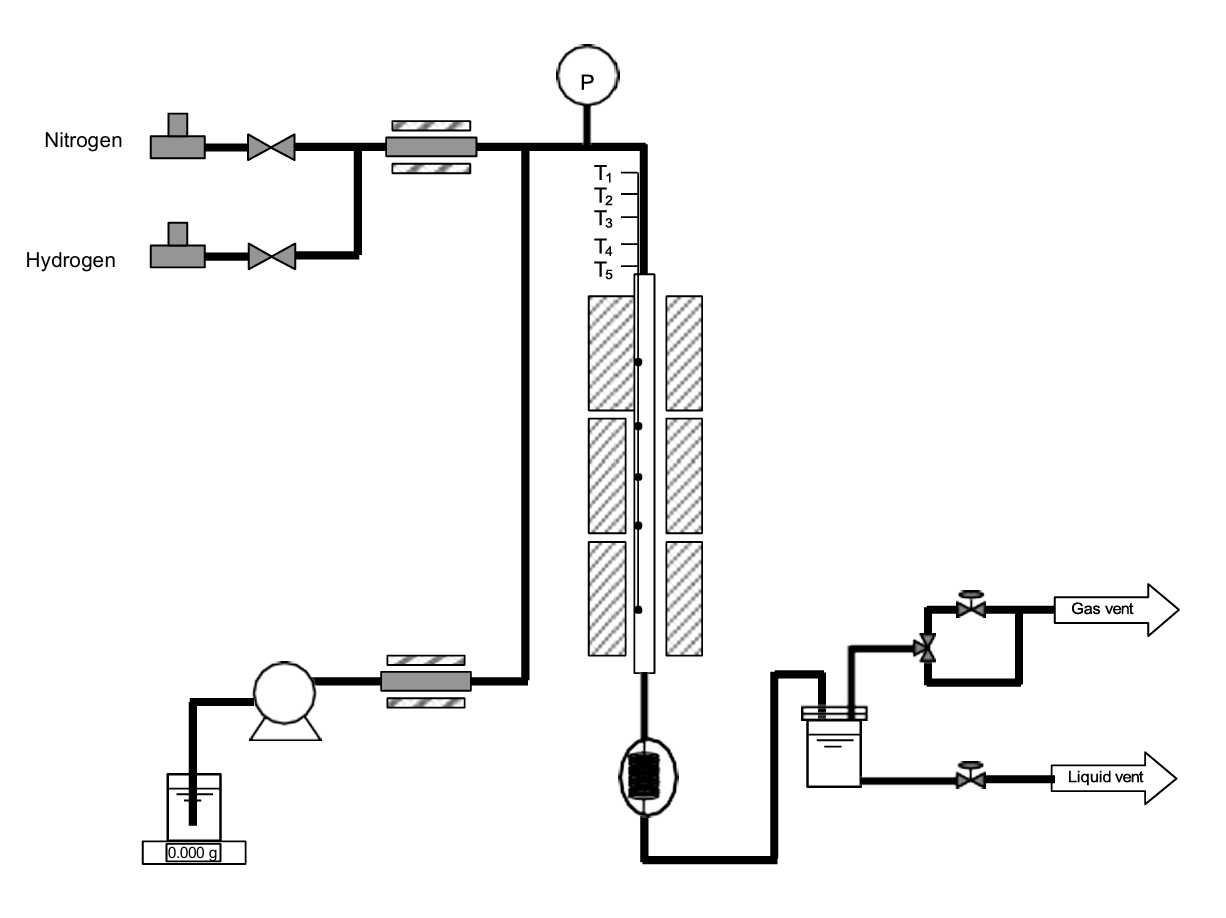

- Biofuels can be derived from various sources, including municipal waste, wood chips, soybeans, and algae. Depending on the source, a different process and thus different reactor design and conditions are used. Below we explore three processes for the production of biofuels in which AMI has participated with a BenchCAT reactor design and construction.

Advanced Measurement Instruments

Copyright 2004–2024 ami-instruments.com

Products

Products

Products

Products

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com