Products

Industry

Products

Industry

- Chemisorption and thermal desorption methods, such as Temperature Programmed Desorption (TPD), are widely utilized for catalyst characterization. These techniques analyze the gases released from a catalyst surface, typically detected using a Thermal Conductivity Detector (TCD) or, in some cases, a mass spectrometer. While they provide valuable insights into the number and strength of active sites, they do not reveal details about the nature of these sites, the type of adsorption, or the presence of multiple adsorption site types.

- To address this limitation, the AMI-300 IR integrates standard AMI techniques with real-time catalyst surface analysis using Fourier Transform Infrared (FTIR) spectroscopy. This innovative approach enables direct observation of adsorbed species, offering a deeper understanding of the adsorption and desorption processes.

-1.png)

- AMI-300 IR shown with integrated Thermo Nicolet iS5 FTIR spectrometer

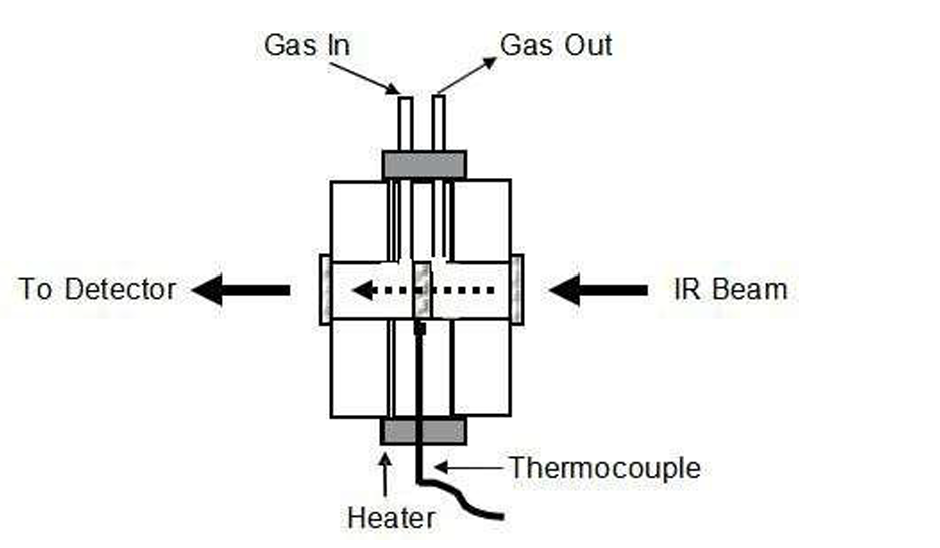

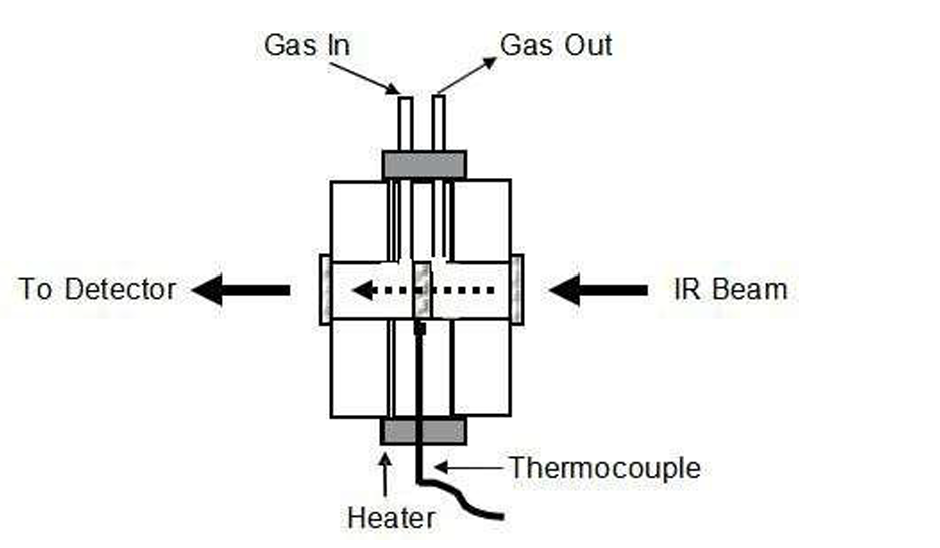

- Sample preparation involves compressing approximately 100 mg of catalyst powder into a thin, self-supported wafer, which is then secured in a proprietary catalyst holder within the IR cell. This configuration allows the IR beam to pass directly through the catalyst wafer, enabling in situ spectroscopic analysis. Figures 2 and 3 illustrate a schematic of the IR cell and a photograph of the actual unit, respectively.

- Once the sample is positioned, it can undergo all standard AMI-300 experimental procedures while simultaneously monitoring surface species and adsorbates using the FTIR spectrometer. Concurrently, effluent gases can be analyzed via the system’s built-in thermal conductivity detector (TCD) or an optional mass spectrometer (MS).

- This integrated analytical approach enables real-time characterization of catalytic processes, providing critical insights into adsorption and desorption phenomena at the molecular level.

- Diagram of IR transmission cell

- IR transmission cell. Heaters and Insulation have been removed for clarity

- An example of the kind of information that can be obtained with this technique is the mode of adsorption and desorption of CO on a platinum surface.

- Once the sample is positioned, it can undergo all standard AMI-300 experimental procedures while simultaneously monitoring surface species and adsorbates using the FTIR spectrometer. Concurrently, effluent gases can be analyzed via the system’s built-in thermal conductivity detector (TCD) or an optional mass spectrometer (MS).

- This integrated analytical approach enables real-time characterization of catalytic processes, providing critical insights into adsorption and desorption phenomena at the molecular level.

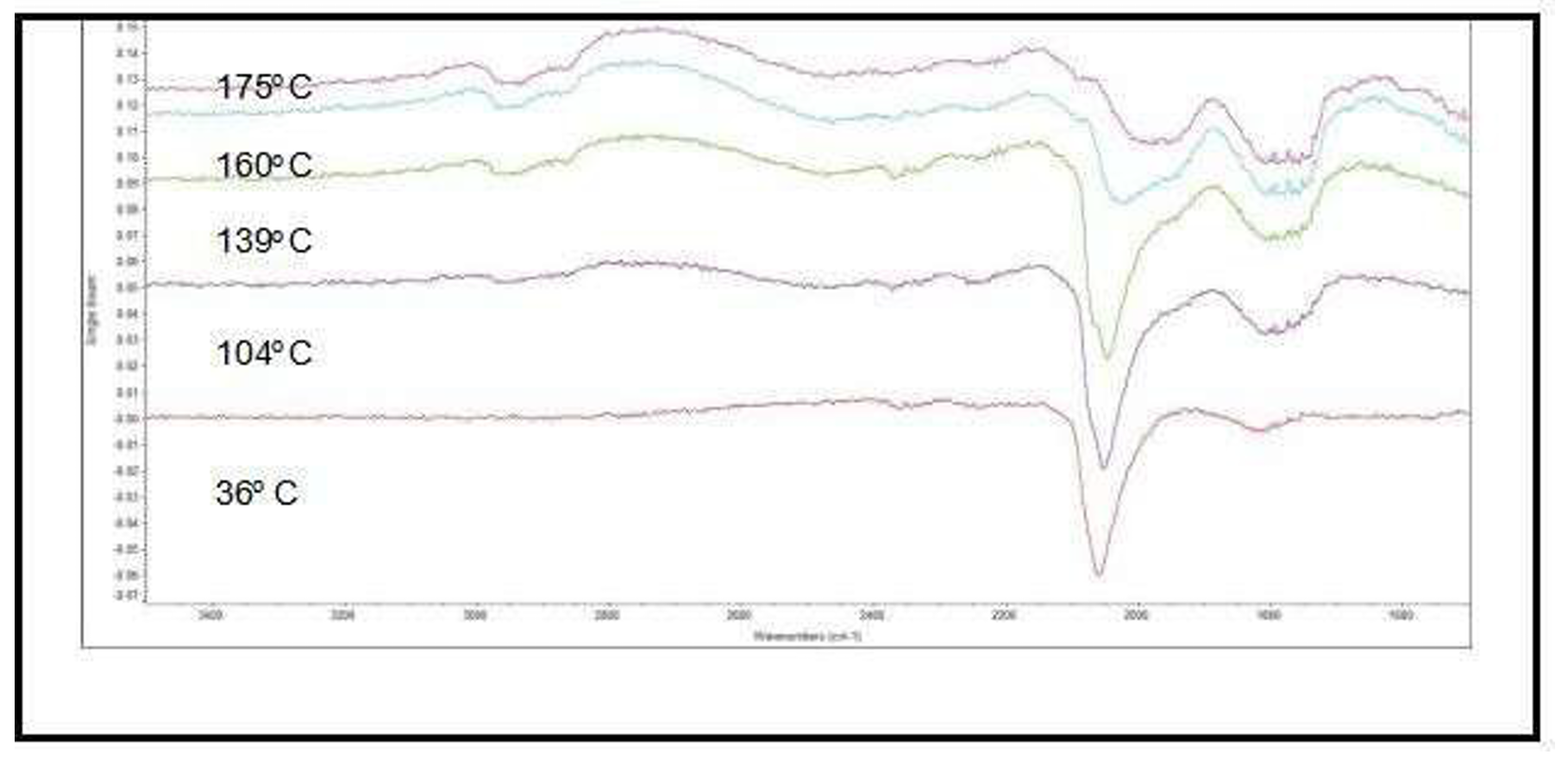

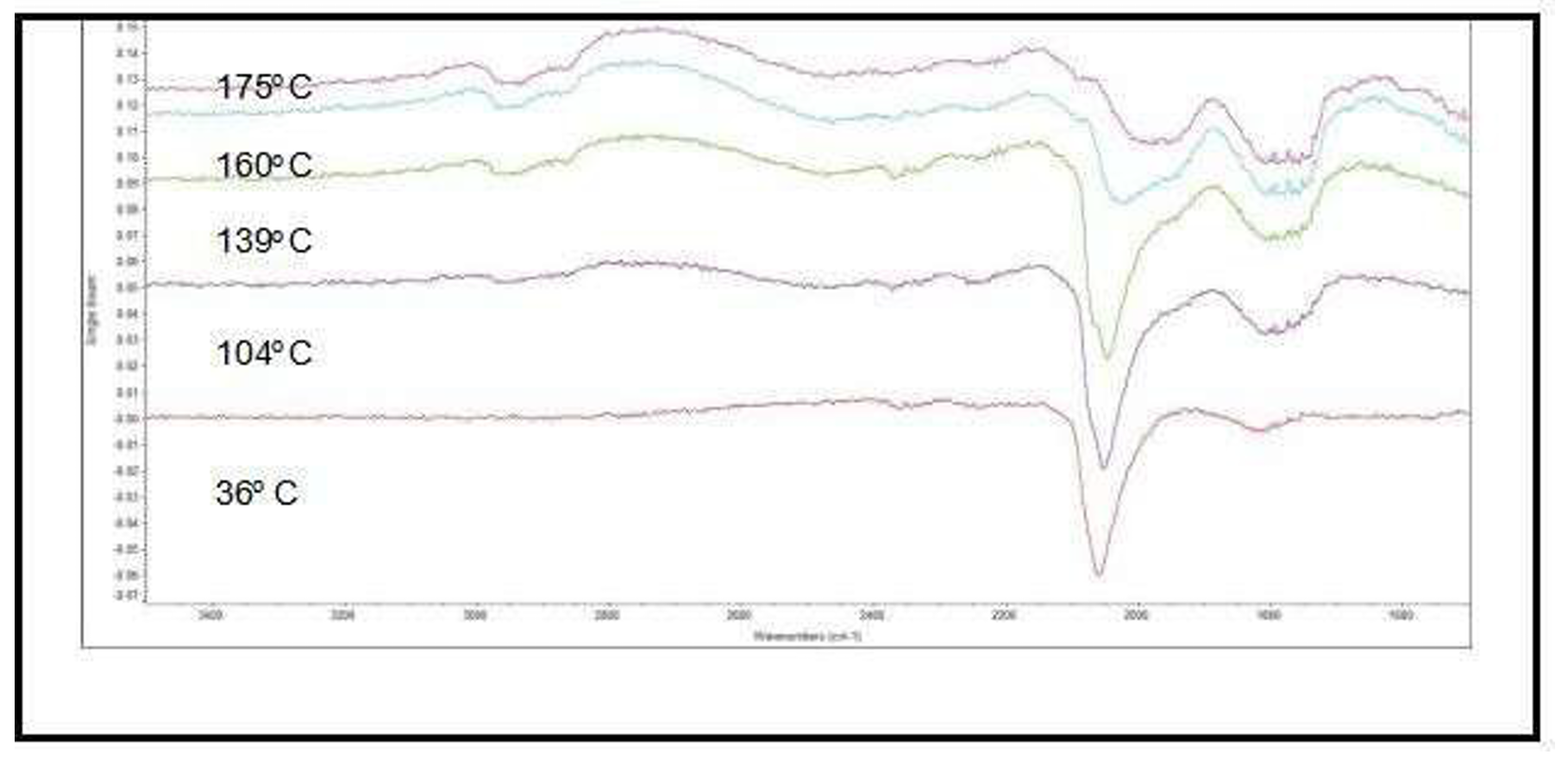

- A 1% Pt/Al2O3 catalyst was pressed into a wafer and mounted on an IR cell. The sample was reduced for several hours at 200°C, cooled to room temperature, and then flushed with inert gas for an hour in order to remove the gas-phase and any loosely held CO. The resulting IR spectrum (background subtracted) showed a single sharp line at approx- imately 2060 cm

- IR spectrum of CO adsorbed on a 1% Pt/Al2O3 catalyst

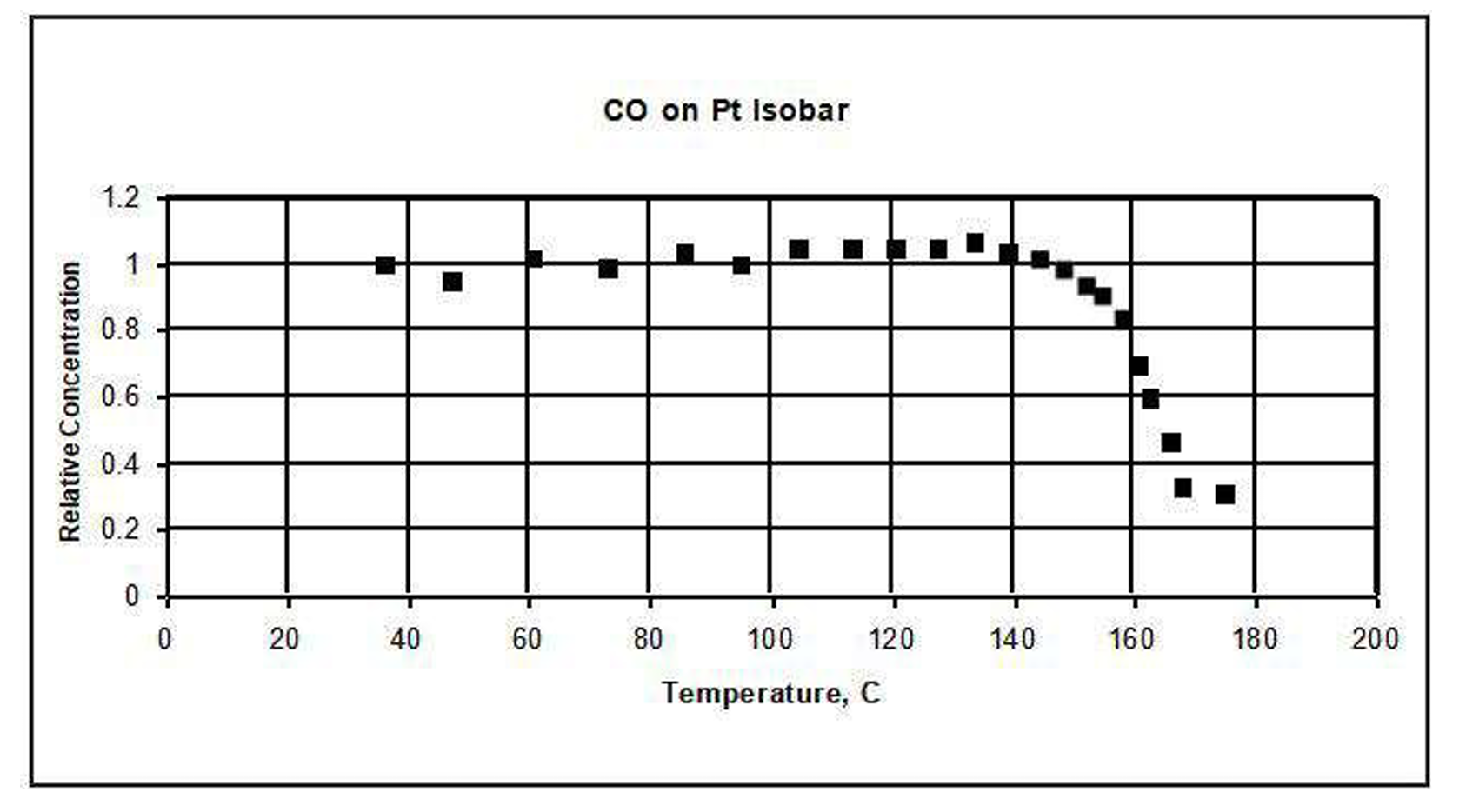

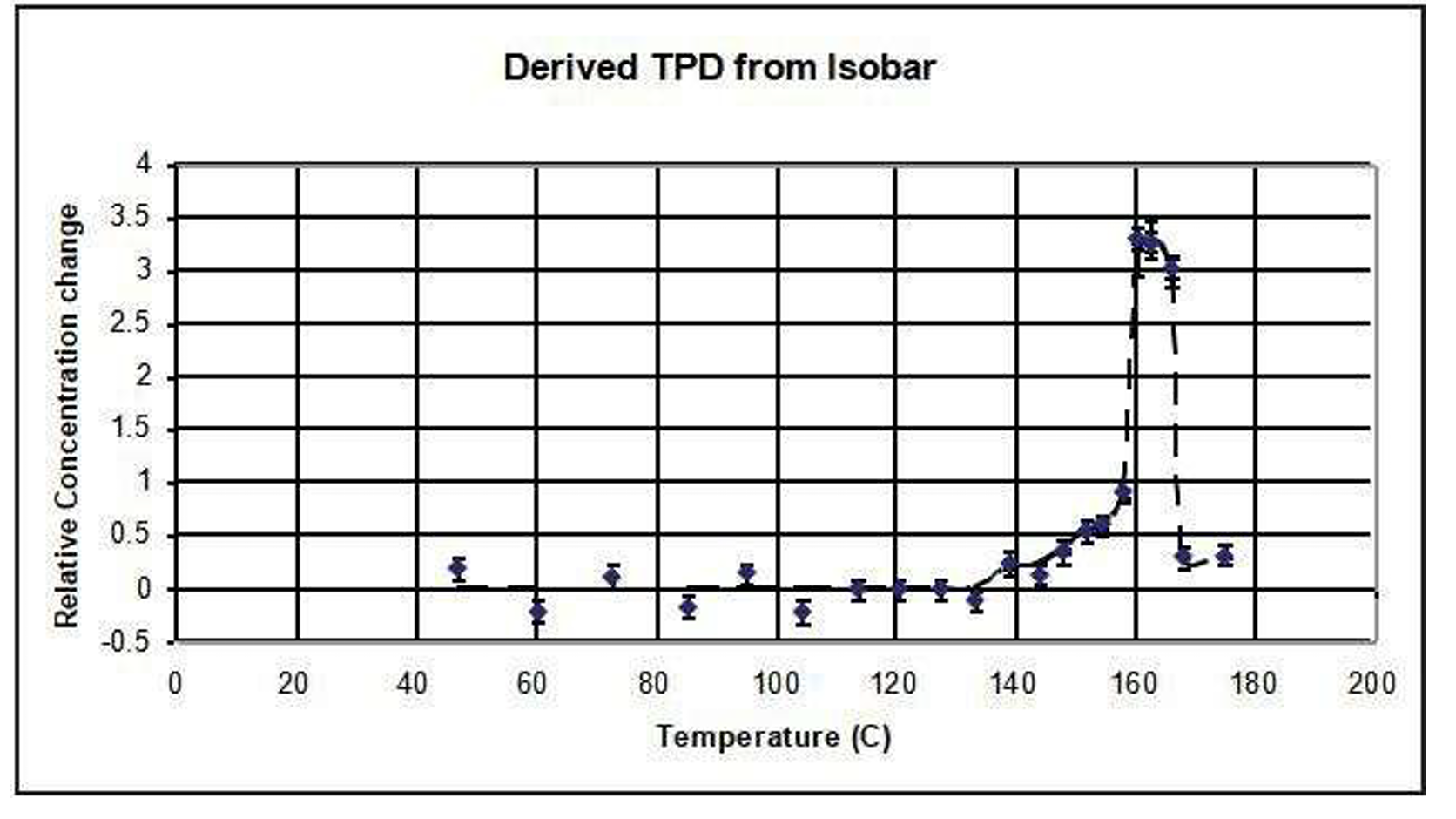

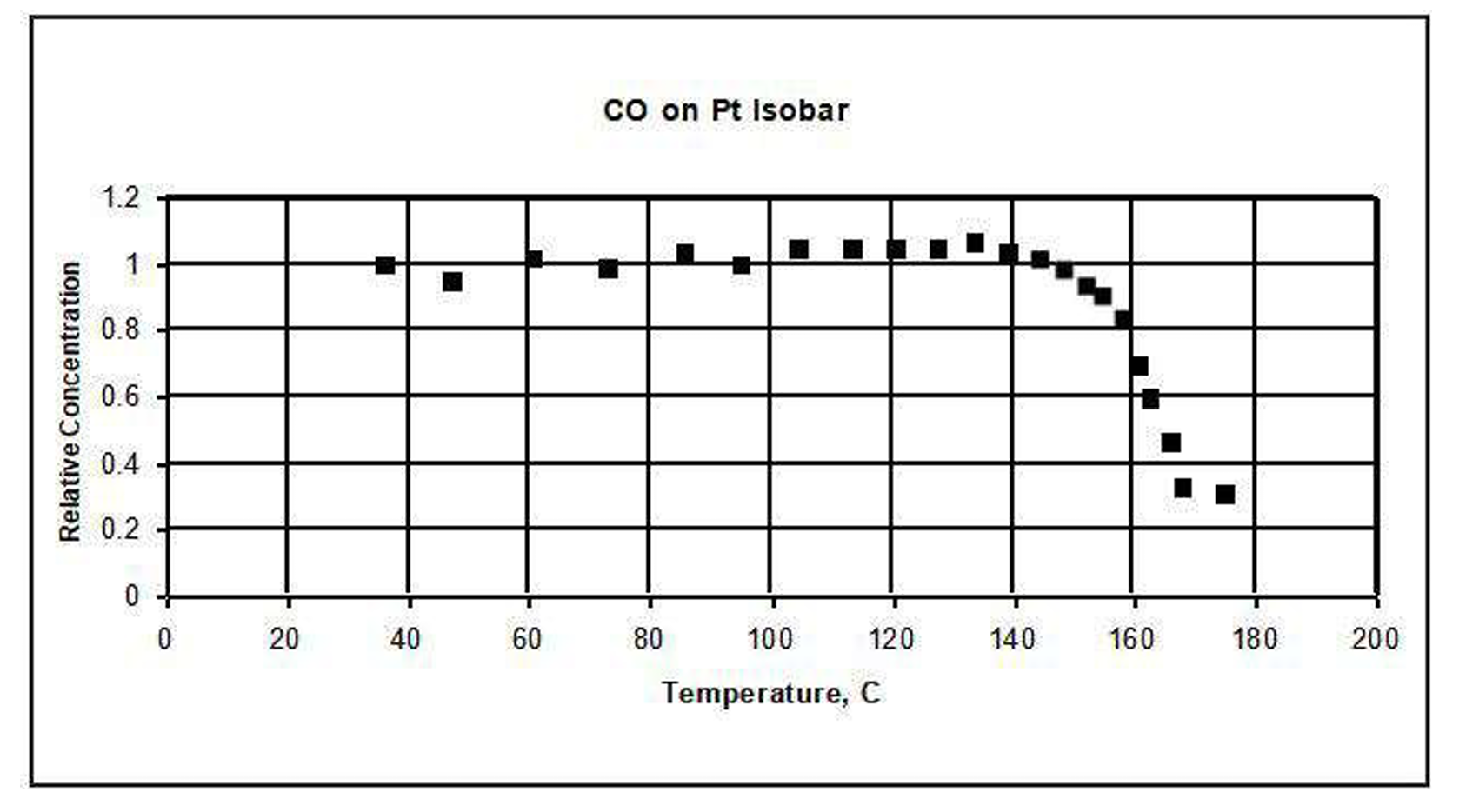

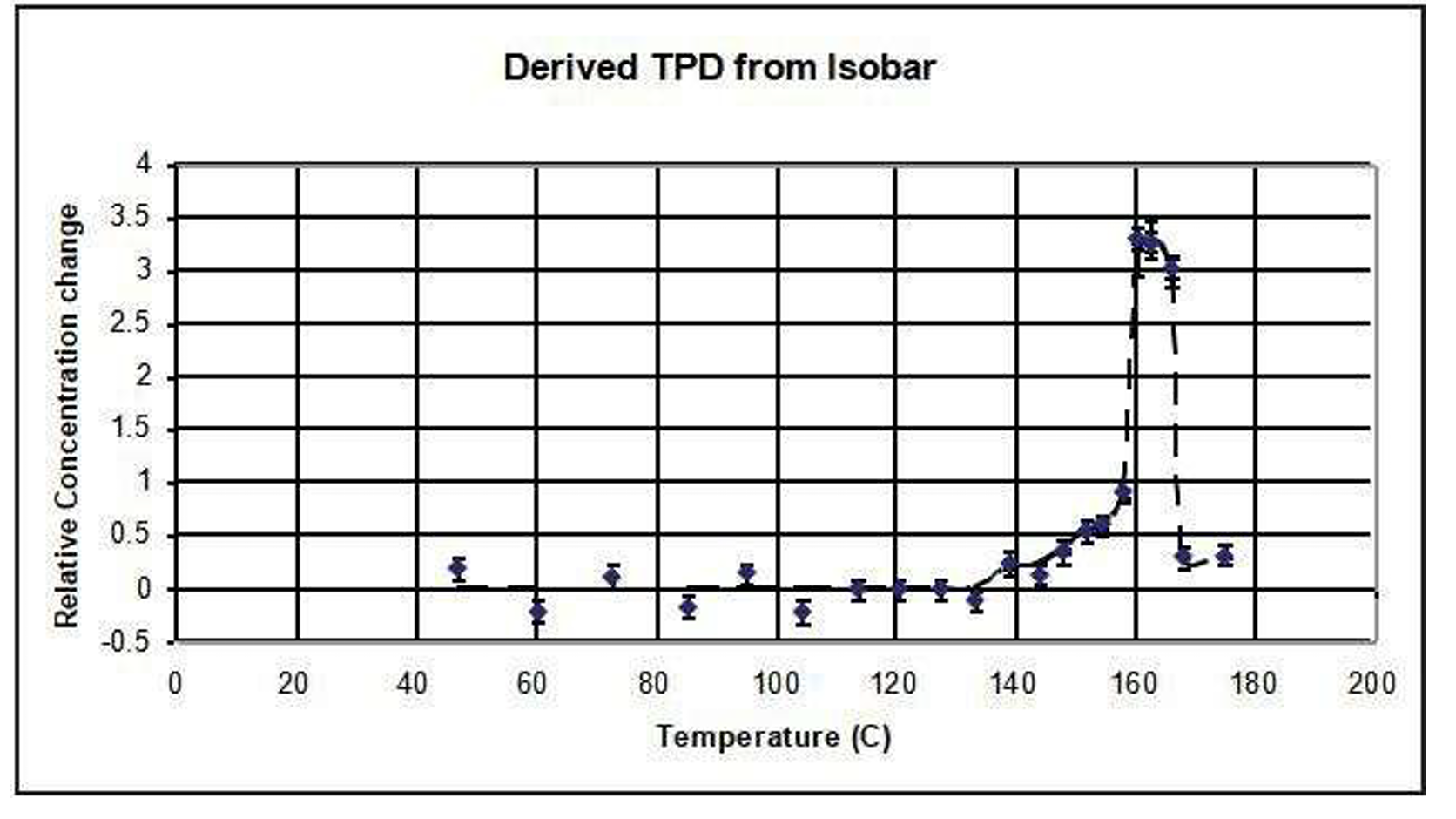

- This sample was then heated and the CO band followed as a function of temperature (figure 5). According to Beer’s Law, absorbance is proportional to concentration so from these measurements it is possible to construct an isobar and from it obtain a derived TPD. These are shown in figures 6 and 7, respectively.

- CO signal as a function of temperature

- Isobar of CO adsorbed on 1% Pt/Al2O3

- Derived CO TPD

DETECTION

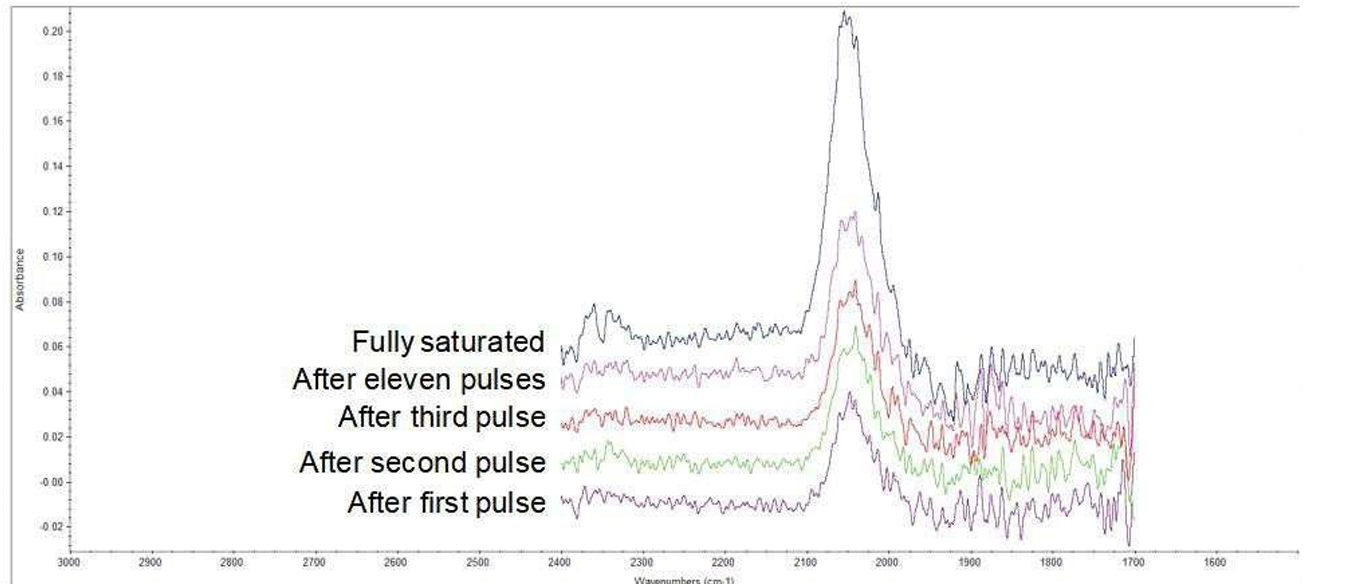

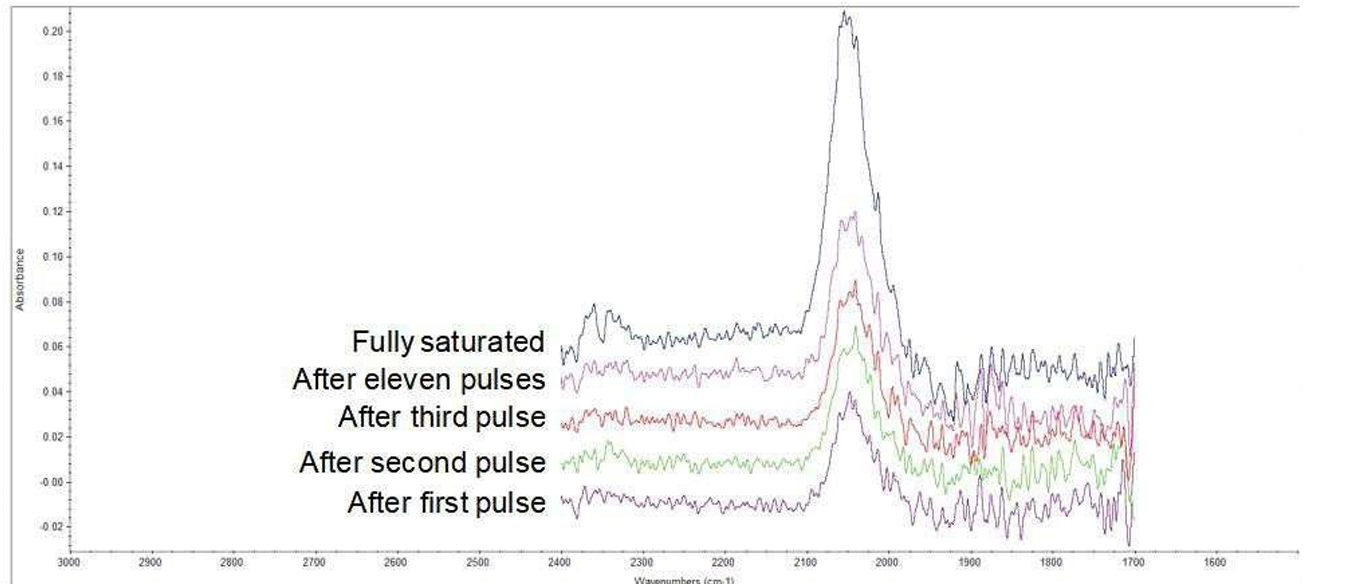

- IR detection can also be used during pulse chemisorption procedures to ascertain the mode(s) of adsorption at different coverages. Figure 8 illustrates the adsorption of CO on platinum as the coverage increases. Even at low coverages, all the CO is adsorbed in a single mode, linearly, and there is no evidence for “bridged” CO. These insights are uniquely obtainable through IR spectroscopy, as it directly analyzes the catalyst surface rather than solely monitoring evolved gases.

- Pulse chemisorption of CO on Pt by FTIR.

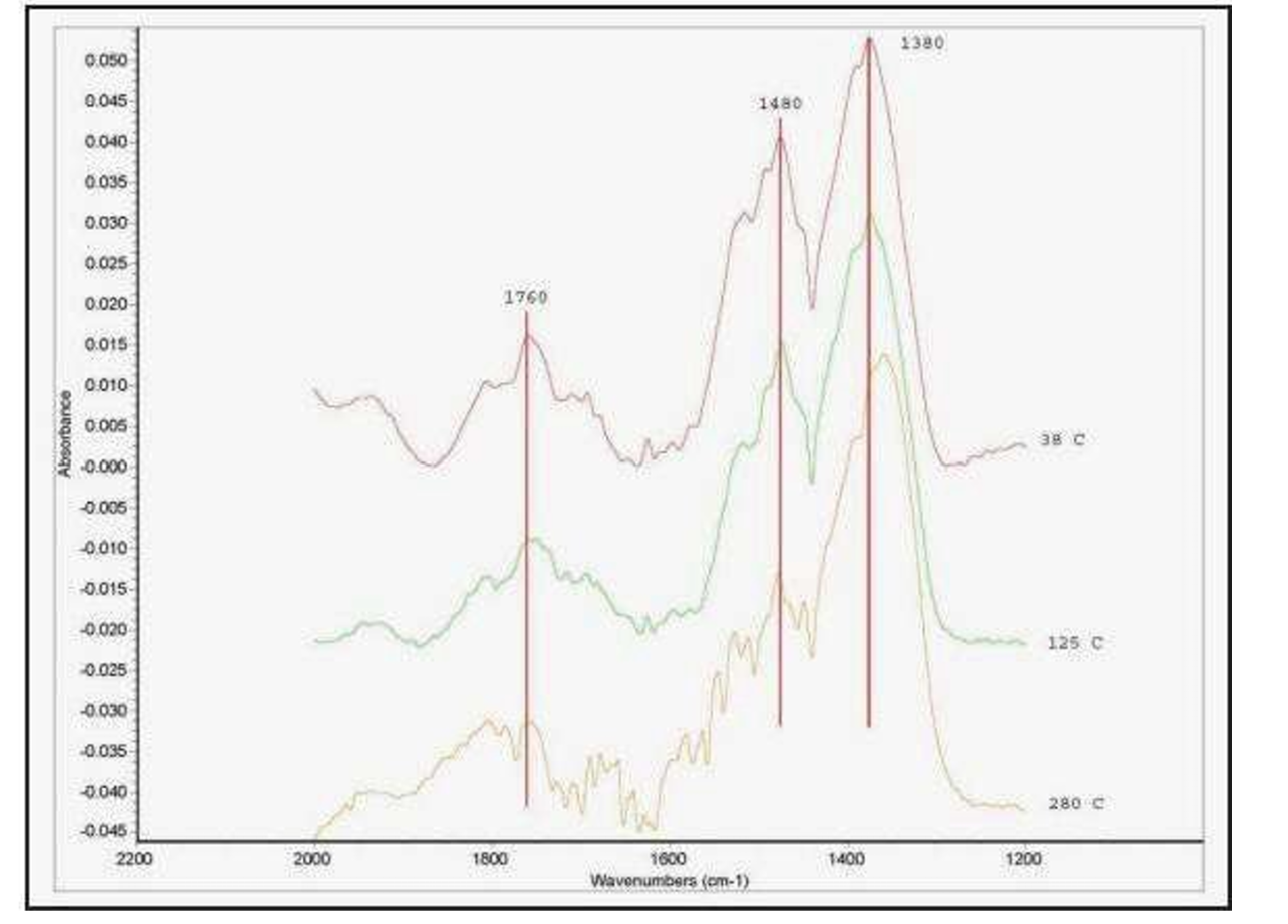

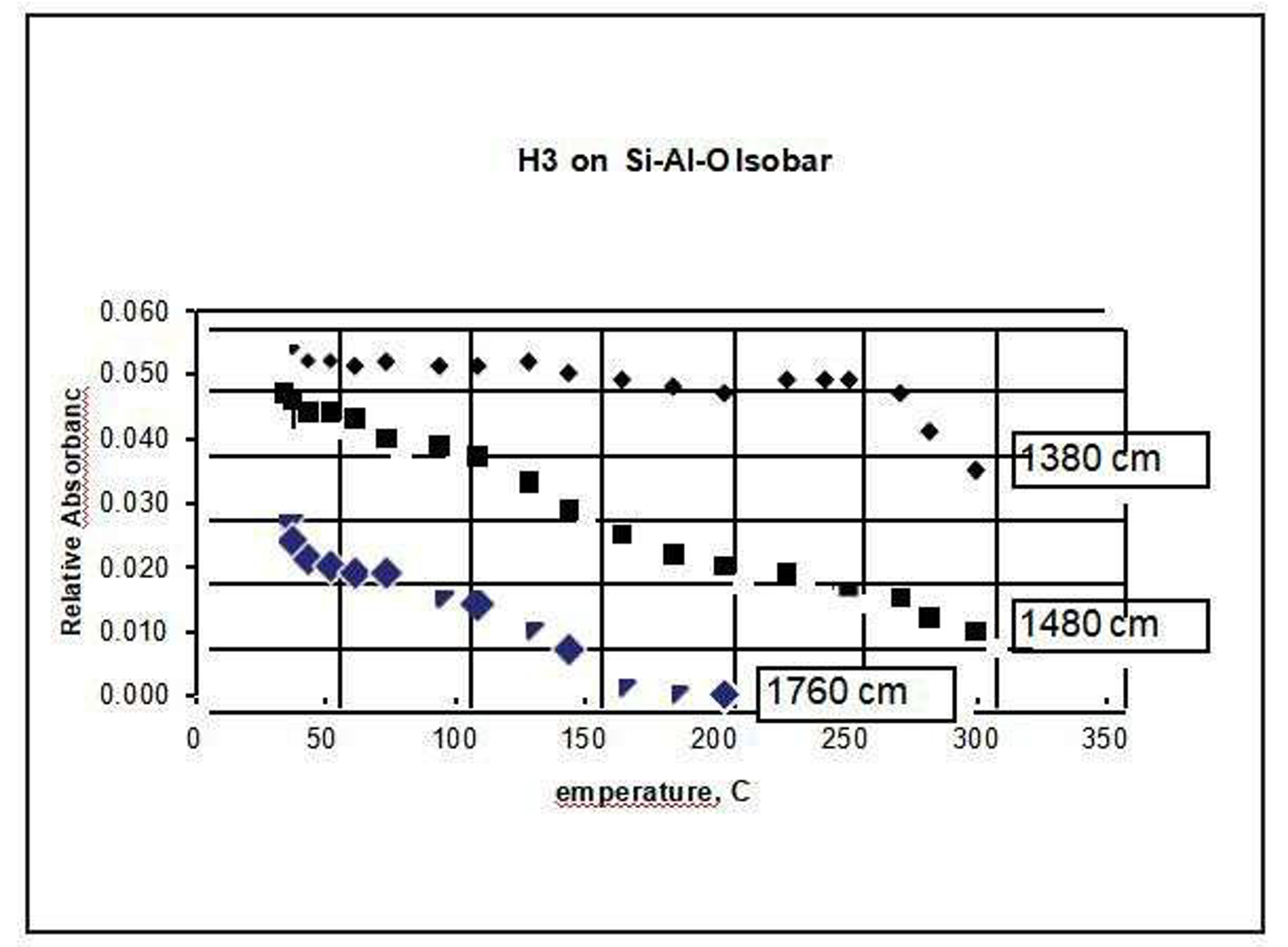

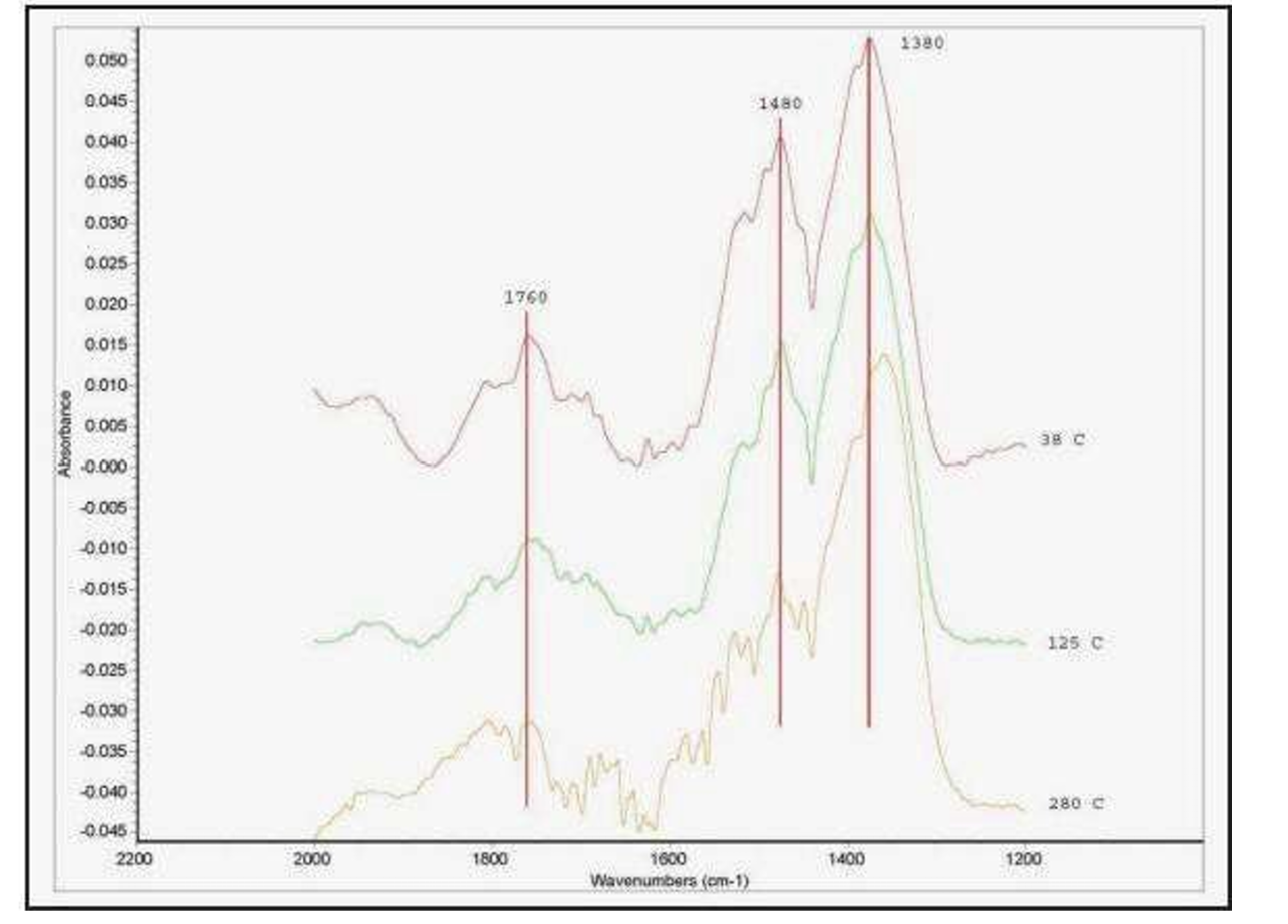

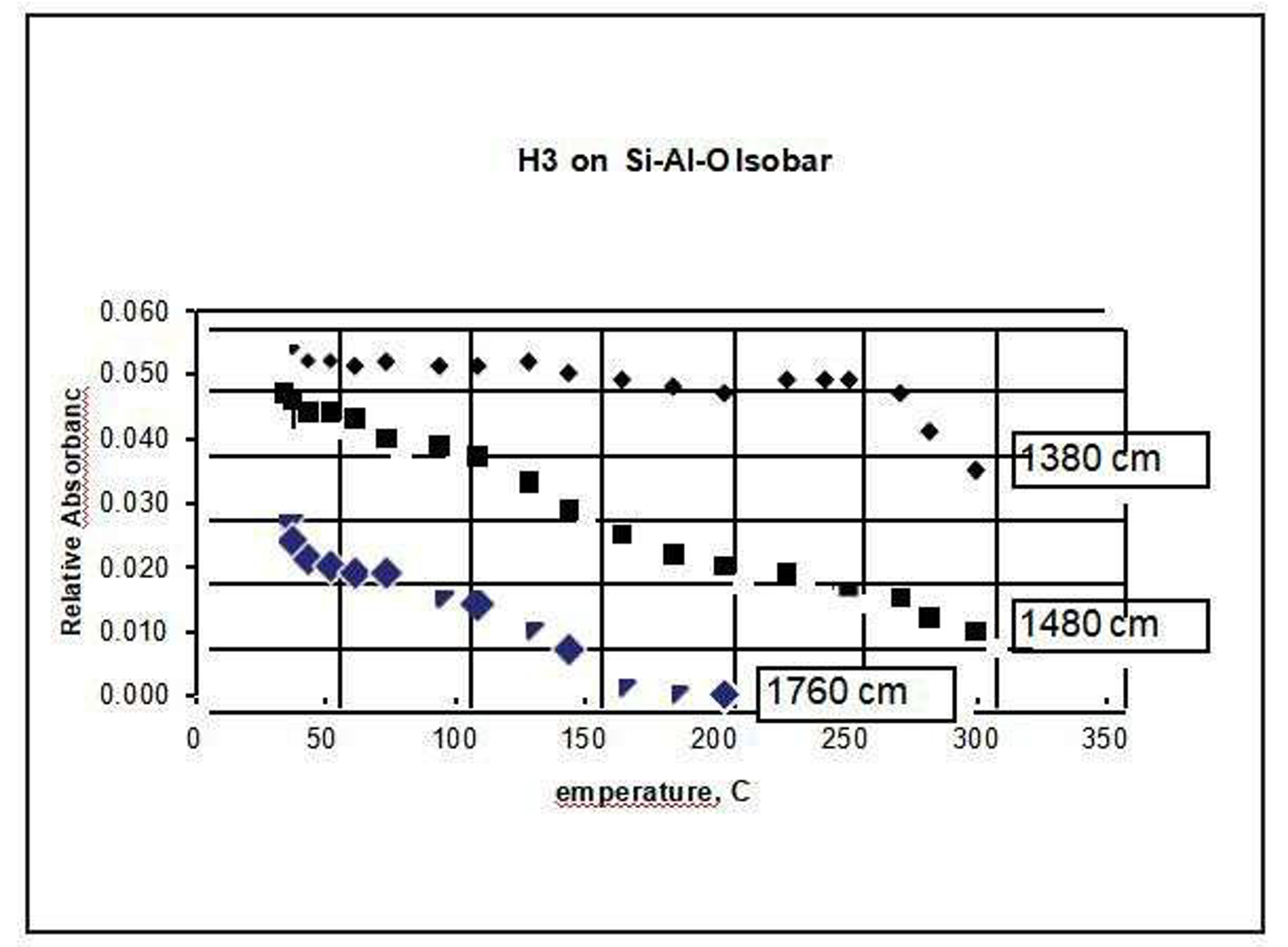

- Ammonia can be used as a probe molecule to determine the magnitude and type of acid sites in a catalyst. Below, in figure 9, is an example of ammonia adsorbed on a silica-alumina material. Three broad bands were identified as belonging to the adsorbed ammonia, at approximately 1760, 1480, and 1380 cm-1. The band at 1480 cm-1 can be ascribed to ammonia adsorbed on Brønsted acid sites, the others to ammonia adsorbed on Lewis sites (see for example, M. Niwa et al., J. Phys. Chem. B, 110 (2006) p. 264). By carrying out temperature programmed experiments and following the absorbance of the three bands as a function of temperature, it is possible to measure the isobars for each type of adsorption and assess the strength of each adsorption process. These isobars are shown in figure 10.

- Ammonia bands on silica-alumina shown at three different temperatures

- Isobars for each of the three main ammonia bands on silica-alumina.

- It can be seen from the data above that the adsorption reflected in the 1380 cm-1 band is more strongly held than the other two, perhaps indicating a stronger Lewis-type bond.

- The AMI-300 IR expands upon AMI’s line of catalyst characterization instruments, which have been continuously developed and manufactured since 1984. By integrating real-time Fourier Transform Infrared (FTIR) spectroscopy with AMI’s standard detection methods, this system enables researchers to not only quantify the number and strength of active sites but also gain direct insights into the nature of adsorption processes.

Products

Products

Products

Products

-1.png)

TEL: +1 262-877-3600

TEL: +1 262-877-3600

EMAIL:sales@ami-instruments.com

EMAIL:sales@ami-instruments.com